In the highly regulated world of American food production, maintaining stringent safety standards and optimizing operational efficiency are critical priorities. As the industry evolves, manufacturers increasingly turn to advanced screening technologies to meet these demands. For those searching for solutions to streamline their processes and ensure product integrity, Vibratory Sifters have emerged as a popular choice, offering a blend of reliability, speed, and precision that is well-suited to the complexities of modern manufacturing.

Enhancing Food Safety Through Advanced Screening

Food safety is a non-negotiable aspect of manufacturing, with contamination posing significant risks to both consumers and businesses. Vibratory sifters play a pivotal role in reducing these risks by efficiently removing foreign particles, oversized materials, and unwanted debris from ingredients and finished products.

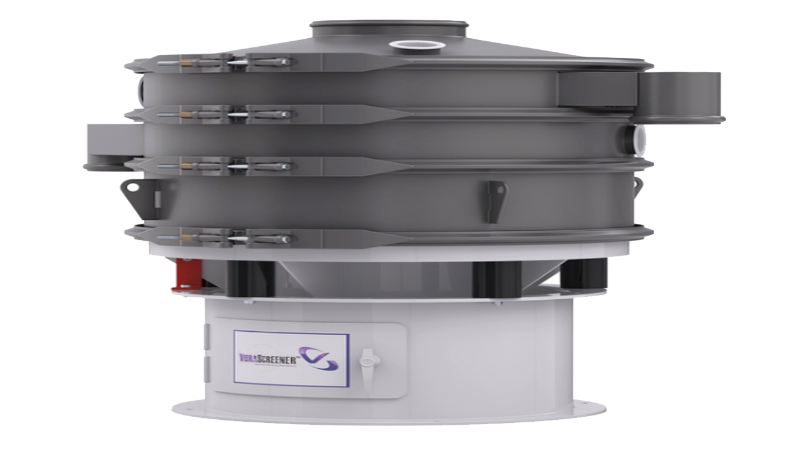

These machines use rapid, multi-directional vibrations to separate materials by size, ensuring that only particles of the desired dimension pass through. This action is especially important in industries processing powders, granules, or liquids, where even minor contaminants can compromise safety and quality.

Key ways vibratory sifters improve food safety include:

• Consistent Particle Separation: By maintaining uniform mesh sizes, sifters ensure a consistent product, reducing the chance of contamination.

• Prevention of Cross-Contamination: Easily cleanable designs allow for quick changeovers between batches, minimizing the risk of allergens or other contaminants transferring between products.

• Compliance with Food Safety Standards: Sifters help manufacturers meet stringent regulatory requirements, including those set by the FDA and USDA.

Boosting Efficiency Across Manufacturing Operations

Beyond safety, efficiency is a driving force in American manufacturing. Vibratory sifters are engineered to maximize throughput while minimizing downtime, making them indispensable for high-volume operations.

Notable efficiency benefits include:

• High Processing Speeds: Vibratory action accelerates the sorting and screening process, enabling manufacturers to process larger quantities in less time.

• Reduced Labor Requirements: Automated sifting reduces the need for manual inspection, freeing up staff for other critical tasks.

• Minimized Product Loss: Precise separation means that only unwanted materials are discarded, reducing waste and maximizing yield.

Additionally, many modern sifters incorporate features such as quick-release clamps and tool-free access, allowing for rapid cleaning and maintenance. This design not only maintains hygiene but also ensures that production lines experience minimal disruption.

Adaptability for Diverse Applications

One of the most significant advantages of vibratory sifters is their adaptability. Whether processing flour, sugar, spices, dairy powders, or liquids, these machines can be tailored to meet the unique demands of various food products. Adjustable mesh sizes, customizable vibration settings, and compatibility with both wet and dry materials make them a versatile asset in any facility.

Looking Ahead: The Future of Food Manufacturing

The American food manufacturing sector is under constant pressure to improve safety, efficiency, and adaptability. Vibratory sifters stand at the forefront of this movement, providing a reliable means to achieve these goals. By integrating advanced screening technology, manufacturers can not only safeguard their products but also enhance productivity and remain competitive in a rapidly evolving marketplace.

In summary, vibratory sifters have become an essential tool for American food manufacturers. Their ability to ensure product purity, streamline operations, and adapt to a variety of applications makes them a smart investment for any business committed to food safety and operational excellence. As the industry continues to advance, the role of efficient screening technology will only become more critical, helping manufacturers meet the ever-growing expectations of regulators and consumers alike.