When critical machinery slows down or suddenly stops working, businesses face costly downtime and lost productivity. For many industrial and commercial operations, electric motors are the heart of their equipment, powering everything from conveyor belts to HVAC systems. Over time, even the most robust motors can experience wear and tear, leading to decreased efficiency and eventual failure. Many facility managers and equipment owners turn to solutions like Electric Motor Rewinding New Jersey to restore their motors and maximize their investment. This service is frequently searched for by those looking to extend the lifespan of their equipment without the high cost of complete replacement.

Understanding Electric Motor Rewinding

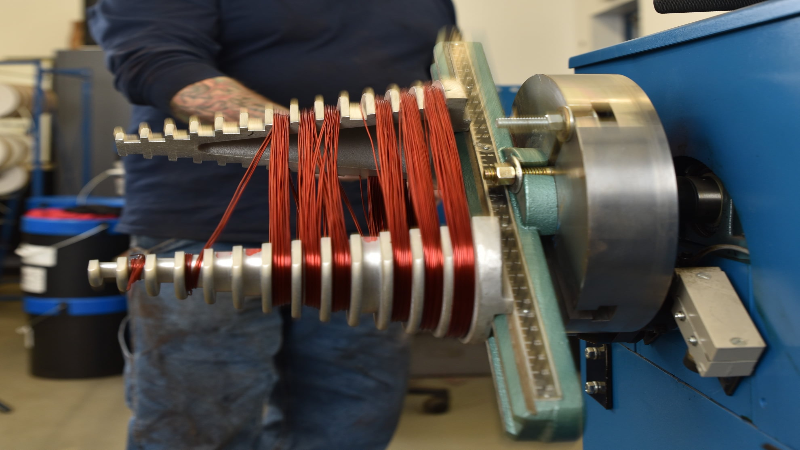

Electric motor rewinding is a specialized repair process that involves removing and replacing the coils of wire within a motor’s stator or rotor. Rather than discarding the entire motor when windings fail, this process restores the motor’s function by replacing the damaged windings with new, high-quality wire. The process requires expertise, precision, and specialized equipment to ensure the repaired motor meets or exceeds its original performance specifications.

Key Steps in the Rewinding Process

-

Inspection and Diagnosis: The motor is thoroughly inspected to identify the cause of failure and assess the condition of components.

-

Disassembly: The motor is carefully disassembled to access the internal windings.

-

Removal of Old Windings: Damaged or burnt windings are removed from the core.

-

Cleaning and Preparation: The motor core is cleaned and prepped for new windings.

-

Rewinding: Technicians wind new coils with the appropriate gauge and insulation.

-

Reassembly and Testing: The motor is reassembled, tested, and balanced to ensure optimal operation.

Benefits of Professional Electric Motor Rewinding

Opting for professional rewinding services offers several advantages over purchasing new equipment:

-

Cost Efficiency: Repairing an existing motor is often significantly less expensive than buying a replacement, especially for large or specialized units.

-

Faster Turnaround: Rewinding can often be completed more quickly than sourcing and installing a new motor, reducing downtime.

-

Sustainability: Extending the life of existing motors helps reduce waste and the environmental impact associated with manufacturing new equipment.

-

Performance Restoration: High-quality rewinding restores the motor’s original efficiency, torque, and reliability.

How Rewinding Extends Equipment Lifespan

Reliable rewinding services address the root causes of motor failure, such as insulation breakdown, overheating, or electrical faults. By replacing worn or damaged windings with new materials and ensuring proper installation, the process gives motors a new lease on life. This not only prevents premature equipment replacement but also maintains overall system performance.

For businesses in New Jersey, regular maintenance and timely rewinding can dramatically extend the useful life of essential machinery. Well-maintained and professionally rewound motors often match or surpass the reliability of new units, especially when combined with updated insulation materials and precision balancing during reassembly.

Ensuring Long-Term Reliability

Choosing a reputable provider for electric motor rewinding is crucial. Experienced technicians use advanced diagnostic tools and adhere to industry standards, ensuring repairs are performed correctly. Additionally, regular inspections and preventative maintenance can identify early signs of wear, allowing for timely intervention before major failures occur.

In summary, electric motor rewinding is a smart, sustainable solution for businesses seeking to maximize equipment longevity and reduce operational costs. By investing in reliable repairs, companies can ensure their critical machinery continues to perform efficiently for years to come, making it a valuable strategy for any operation dependent on electric motors.