In aerospace engineering, precision matters. Every component—from wing structures to thermal shields—must be lightweight, durable, and capable of withstanding extreme conditions. That’s why aerospace companies depend on finite element analysis software to test, validate, and improve designs before anything ever flies.

Virtual Testing for Real-World Conditions

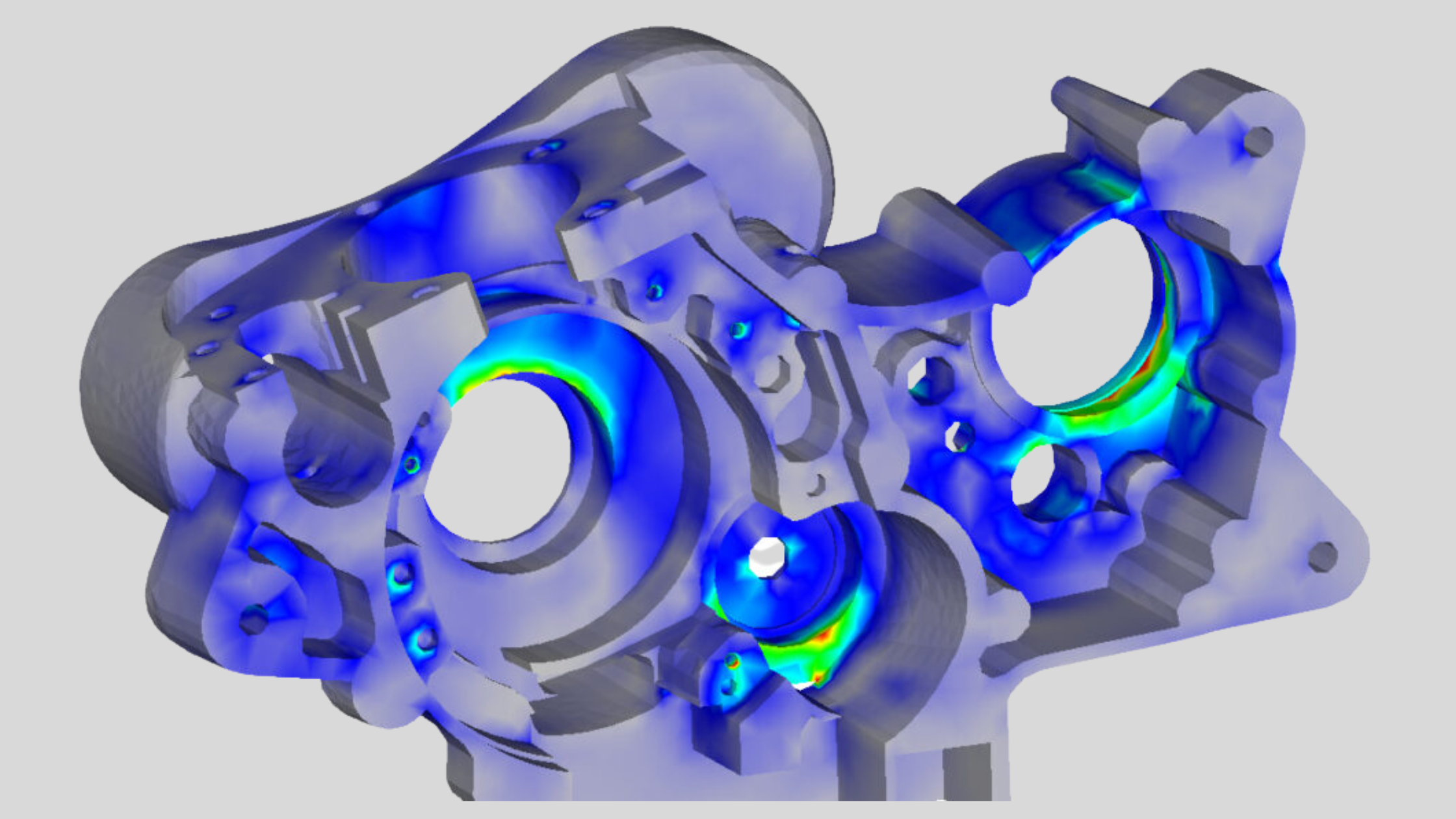

With finite element analysis software in Washington, DC, engineers can model stress, strain, thermal expansion, and vibration behavior under mission-specific conditions. Whether simulating the structural integrity of an aircraft fuselage or evaluating fatigue in satellite brackets, FEA tools let teams test complex interactions virtually—saving time, cost, and weight.

Trusted Tools for Complex Aerospace Programs

For aerospace teams in Washington, DC and across the United States, platforms like Siemens Simcenter Femap are widely adopted for their ability to handle high-fidelity models, nonlinear materials, and advanced meshing. Because it’s solver-independent and CAD-neutral, Simcenter Femap integrates easily into existing workflows, making it ideal for multi-vendor or legacy programs.

Unlike basic simulation tools, finite element analysis software used in aerospace must deliver reliable results under tight constraints. Engineers often need to meet safety standards, optimize for load paths, and validate against both physical testing and digital twin models. FEA software supports this by enabling detailed analysis across temperature, pressure, and dynamic load scenarios.

Simulation Support from Aerospace Experts

At SDA Software, we work with aerospace clients to integrate FEA into real-world processes—from small subsystem modeling to full airframe simulations. Our team provides expert support, training, and setup so engineers can focus on performance and compliance, not just software setup. Learn more on our website at sdasoftware.com or contact us directly at 1-703-935-2832.